木材雕刻機報價,激光刻字機價格多少,木材激光雕刻機,木材激光切割機

木材雕刻機價格,木材激光刻字機價格多少,木材激光雕刻機廠家,木材激光切割機價格

小型激光刻字機價格,激光雕刻機價格,小型木材雕刻機,大型激光雕刻機

co2小型激光刻字機價格,CO2激光雕刻機價格,小型木材雕刻機價格,大型激光雕刻機價格

激光刻字設備,co2激光刻字設備,激光雕刻切割機價格

激光刻字設備廠家,co2激光刻字設備廠家,co2激光雕刻切割機價格

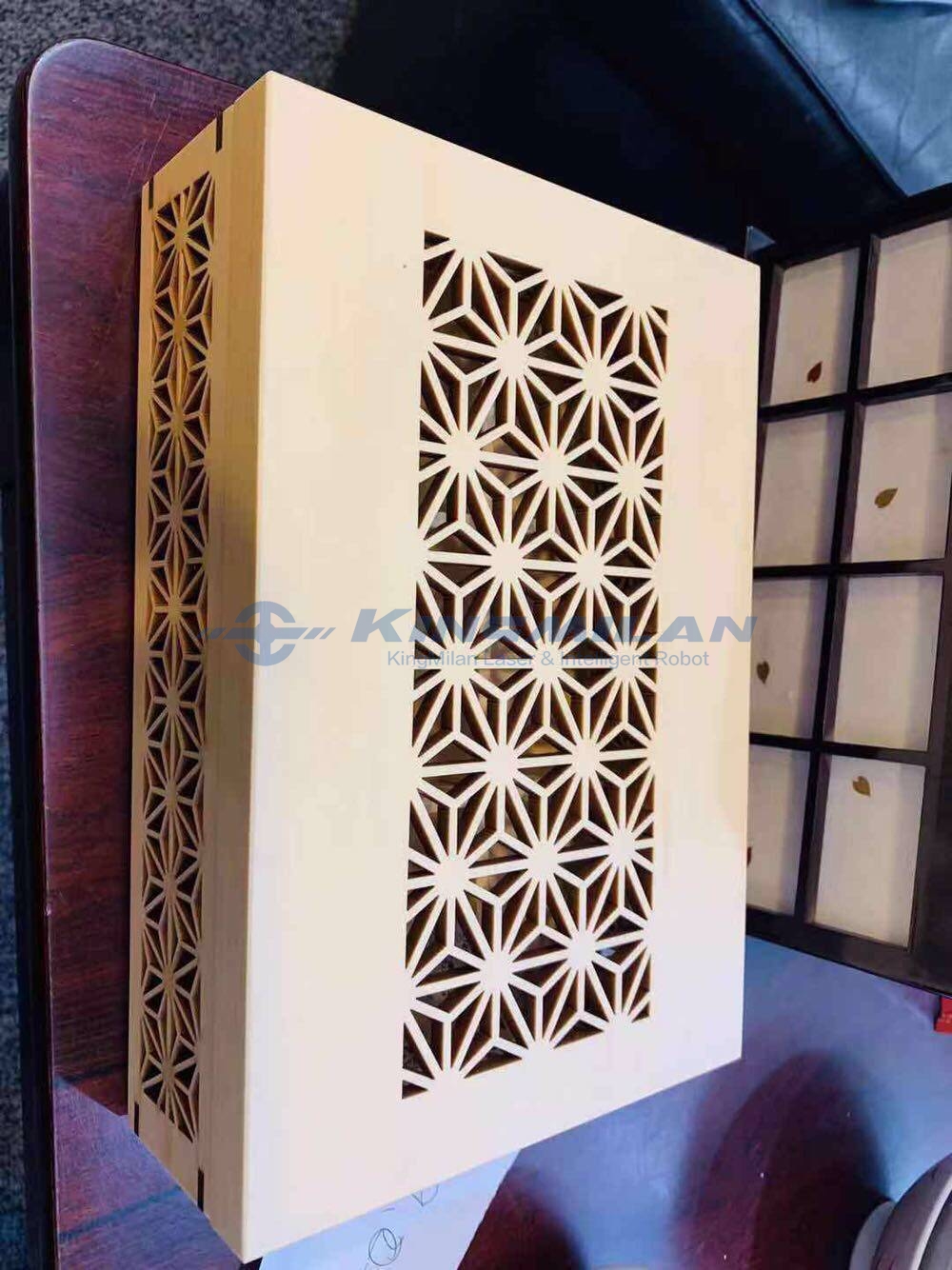

木材切割雕刻,木材激光切割雕刻,co2木材切割雕刻,木材co2激光切割雕刻;

凹片雕刻,木質凹片雕刻,木質凹片雕刻機,co2木質凹片雕刻,木質凹片激光雕刻

凸版雕刻,木質凸版雕刻,木質凸版雕刻機,co2木質凸版雕刻,co2木質凸版雕刻機;

玻璃切割雕刻,玻璃激光切割雕刻,玻璃木材切割雕刻,玻璃co2激光切割雕刻;

木質激光雕刻機:

木材激光雕刻機一般用于木材加工的切割和雕刻,木質材料激光雕刻形式可分為切割雕刻、凹模雕刻和凸模雕刻三種。激光雕刻的材料去除原理與激光切割相同,多條未切透的切槽連在一起就形成成面積的材料去除。激光切槽的橫截面呈“V”形,切割速度越低、激光電流越大,切槽寬度和深度也越大,其中切割速度和激光電流對切槽深度的影響程度比對切槽寬度大得多。

木質材料激光雕刻加工的基本原理與激光切割加工基本相同,都是利用高能量密度的激光束轉化為熱能,瞬時引起木材熱分解和炭化,從而去除部分材料。激光切割是將木質材料(主要是板材)的不同部分分離開,而激光雕刻是在木質材料的表面加工出要求的圖 案、花紋和文字等。對同一木板講,激光切割所需的能量較大,而激光雕刻由于不需要切透工件,故所需的能量相對較小。激光雕刻是非接觸式加工方法,與傳統機械加工方法相比具有無木屑污染、無刀具磨損也不需更換刀具、無噪聲污染(噪聲很低)等優點。激光切割頭聚焦透鏡將激光聚焦至一個很小的光斑,光斑直徑一般為0.1~0.5mm。激光束焦點位于待加工表面附近,用以熔化或汽化被加工材料。與此同時,與光束同軸的氣流由切割頭噴出,將熔化或汽化了的材料由切口底部吹出。

技術優點:

金米蘭激光研發團隊從根本上解決因激光設備對各類木材料雕刻切割時出現的速度慢、雕刻深度淺、切割邊鋸齒狀、邊線不光滑等缺點。同時可以采用視覺定位等最新技術有效解決精密切割、高速雕刻技術難題。

Wood engraving machine offer, laser engraving machine price, wood laser engraving machine, wood laser cutting machine

Wood engraving machine price, wood laser engraving machine price, wood laser engraving machine manufacturer, wood laser cutting machine price

Small laser cutting plotter price, laser engraving machine price, small wood engraving machine, large laser engraving machine

Co2 small laser cutting plotter price, CO2 laser engraving machine price, small wood engraving machine price, large laser engraving machine price

Laser engraving equipment, co2 laser engraving equipment, laser engraving and cutting machine price

Laser engraving equipment manufacturers, co2 laser engraving equipment manufacturers, co2 laser engraving and cutting machine prices

Wood cutting engraving, wood laser cutting engraving, co2 wood cutting engraving, wood co2 laser cutting engraving;

Grooved engraving, wood concave engraving, wooden concave engraving machine, co2 wooden concave engraving, wooden concave laser engraving

Letterpress engraving, wood letterpress engraving, wood letterpress engraving machine, co2 wood letterpress engraving, co2 wood letterpress engraving machine;

Glass cutting engraving, glass laser cutting engraving, glass wood cutting engraving, glass co2 laser cutting engraving;

Wood laser engraving machine:

Wood laser engraving machine is generally used for cutting and engraving of wood processing. The laser engraving form of wood material can be divided into three types: cutting engraving, concave engraving and punching engraving. The principle of material removal by laser engraving is the same as that of laser cutting. A plurality of uncut slots are joined together to form an area of material removal. The cross section of the laser grooving is "V". The lower the cutting speed, the larger the laser current, the larger the grooving width and depth. The cutting speed and laser current affect the grooving depth more than the grooving width. Much more.

The basic principle of laser engraving of wood materials is basically the same as that of laser cutting. They use high-energy density laser beams to convert into thermal energy, which instantaneously causes thermal decomposition and charring of wood to remove some materials. Laser cutting separates different parts of the wood material (mainly the board), while laser engraving processes the required patterns, patterns and text on the surface of the wood material. For the same board, the energy required for laser cutting is large, and laser engraving requires relatively little energy because it does not need to cut through the workpiece. Laser engraving is a non-contact processing method. Compared with traditional machining methods, it has the advantages of no wood chip contamination, no tool wear, no need to change tools, no noise pollution (low noise). The laser cutting head focusing lens focuses the laser to a small spot with a spot diameter of typically 0.1 to 0.5 mm. The focus of the laser beam is located near the surface to be machined to melt or vaporize the material being processed. At the same time, the airflow coaxial with the beam is ejected by the cutting head, and the melted or vaporized material is blown out from the bottom of the slit.

Technical advantages:

The Kingmilan laser R&D team fundamentally solves the shortcomings of slow speed, shallow engraving depth, jagged edges and unsmooth edges caused by laser equipment for various types of wood materials. At the same time, the latest technologies such as visual positioning can be used to effectively solve the problems of precision cutting and high-speed engraving.

在線觀看視頻建議:

1、在有無線wifi環境下觀下,更加流暢;

2、打開視頻后,因為網絡流量原因,可以等待一會進行視頻緩沖,通過進度條可以動態觀察緩沖情況,利于更加流暢觀看;

3、也可以進入Kingmilan Laser官方YouTube進行觀看,https://www.youtube.com/channel/UCNbpZhLIdAvvj9N0AtqpTvQ?view_as=subscriber;請訂閱Kingmilan Laser 官方YouTube,里面有更多培訓及應用視頻。

4、任何建議,請與[email protected],或與13390833836,13338036882,13338036889,我們非常感謝;

5、請把本培訓視頻網頁進行收藏或網頁添加到書簽中,這個很重要;

Watch video suggestions online:

1, in the wireless wifi environment, more smooth;

2. After the video is opened, because of the network traffic, you can wait for a video buffer. You can dynamically observe the buffer status through the progress bar, which facilitates smoother viewing.

3. You can also watch it on the official YouTube of Kingmilan Laser,https://www.youtube.com/channel/UCNbpZhLIdAvvj9N0AtqpTvQ?view_as=subscriber ;Please subscribe to official YouTube of Kingmilan Laser for more training application videos

4. Any suggestion, please contact [email protected],[email protected],,WhatsApp/Tel:+86-13390833831,13338036880,we are very grateful;

5. Please add this training video web page to your bookmarks or bookmarks. This is very important;

Sushi box laser cutting-壽司木盒激光切割-283-20181231*必填項

金米蘭特色服務

北京-13390833832

上海-13328035658

山東-13338036882

浙江-13338036883

江蘇-13338036889

安徽-13390833836

福建-13390838052

監督-13390833831

金米蘭噴碼機*必填項